China Manufacture Australia Standard Luxury Galvanized Light Gauge Steel Villa

China Manufacture Australia Standard Luxury Galvanized Light Gauge Steel Villa

Benefits of light gauge steel framing system:

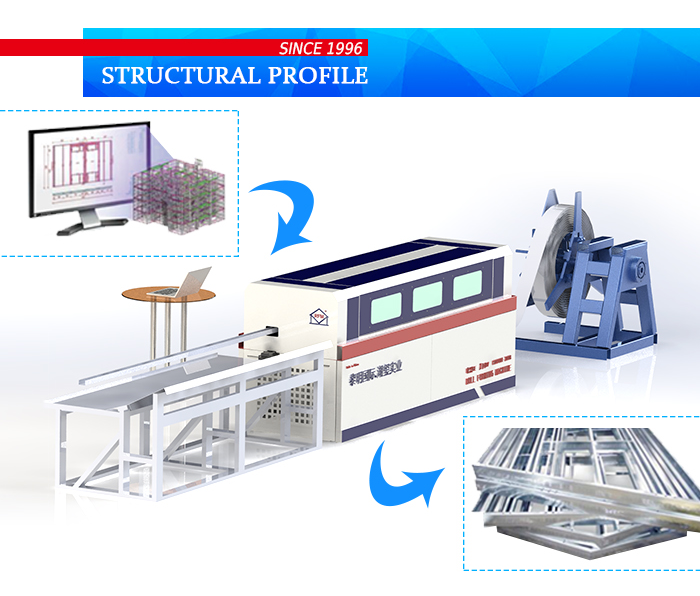

Buildability: the use of pre-fabricated and pre-assembled steel components reduces site works, reduces material waste and improves quality.

Speed: this system requires a shorter construction period compared to that for a conventional system.

Strong but lightweight: steel has one of the highest strength-to-weight ratios of any construction material. This results in savings in the foundation required and the lightness also makes for easier on-site handling.

Safety: steel’s inherent strength and non-combustible qualities enable light steel frame houses to resist such devastating events as fires, earthquakes, and hurricanes. Homes can be designed to meet the highest seismic and wind load specifications in any part of the country.

Quality: a better quality finished house that is durable and low in maintenance.

Easy to remodel: remodeling can be easily accomplished. Non-load bearing walls can be readily relocated, removed or altered.

Design flexibility: because of its strength, steel can span longer lengths, offering larger open spaces and increased design flexibility without requiring intermediate columns or load bearing walls.

Recyclable: all steel products are recyclable.

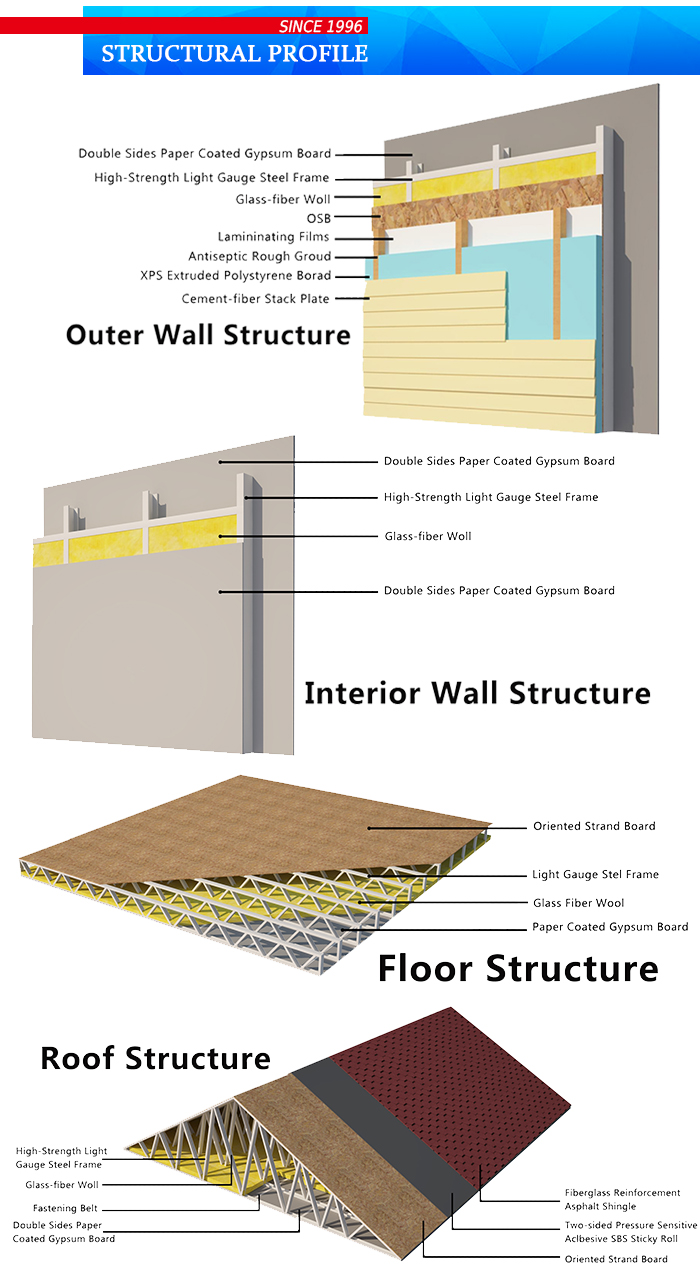

Building's Part | Description | Specification |

Major Structure | Major Structure | Steel Frame | HANGANG Chinese Standard,G550-Z275 C-shaped Steel | According to design requirements |

Consumables | Screw,bent parts,L parts,etc | According to design requirements |

Roof | Deco Layer | Fiberglass reinforcement asphalt shingle | Standard 3mm thick |

Ceiling Insulation | Glass wool blanket | 100mm thick,18kg/m³ |

Structural Layer | Oriented Strand Board | 1220*2440*12,waterproof type |

Waterproof Layer | Waterproof roll | Two-sided Pressure Sensitive Adbesive SBS Sticky Roll |

Cornice | Oriented Strand Board | 1220*2440*12,waterproof type |

PVC cornice closure plate | white |

Outer Wall | Outer Deco Layer | Vantilation Shutters | Vantilation |

Fiber-cement stack plate | 3600*210*8 |

Filled Layer | Glass wool blanket | 100mm thick,18kg/m³ |

Insulating Layer | XPS extruded polystyrene board | Grade B1,1200*600*50 |

Rough Groud | Rough ground | antiseptic treatment,40*50 |

moisture proffing course | Lamininating films | 0.35mm,unidirection |

Structural Layer | Oriented Strand Board | 1220*2440*9, |

Interior Wall | Dry Area | Paper double drywall | 1200*2400*9.5, |

Wet Area | Monolayer cement fiber board | 1200*2400*10 |

Floor | Floor | Oriented Strand Board | 1220*2440*18, |

Door & Window | Entry Door | Steel Security Doors | 900*2100 |

Window | Aluminum Alloy Window | Double Glass Insulation Window |

(Please send an inquiry to us )

(Please send an inquiry to us )